1. A fixture, or “jig”, is any tooling that holds a part in a

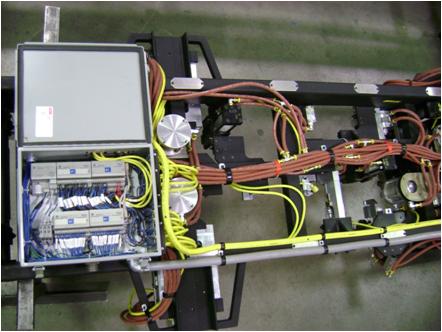

consistent location prior to the welding process. Types Include:

a. No clamping

b. Manual Clamping

c. Pneumatic Clamping

d. Hydraulic Clamping

e. Fully Automatic w/ Robotic Interfacing

The type of tooling you choose depends on many factors, all of which

you have control of.

2. Robot Definition:

a. 1 a: a machine that looks like a human being and performs

various complex acts (as walking or talking) of a human being;

also : a similar but fictional machine whose lack of capacity

for human emotions is often emphasized b: an efficient

insensitive person who functions automatically. 2: a device

that automatically performs complicated often repetitive tasks.

3: a mechanism guided by automatic controls. -

http://www.merriam-webster.com

3. Operator Dependent vs. Tooling Functionality

a. Can you depend on the operator to correctly load parts or should

the tooling decide that for the operator

i. Risks include robot crashing, tooling destruction, or

incorrect parts

b. A robot cannot interact with the piece parts as effectively and

efficiently as a human.

4. Capacity of Robot to “Think for Itself”

a. If welding wire is 0.040” in diameter, than the gap between the

parts being joined must not exceed this.

i. Welding wire will pass through and reach fixture

b. A robot can verify that the parts are seated correctly by

“touch sensing”, or a PLC can tell it that all parts are

present. However, this adds considerable cycle time and/or

cost.