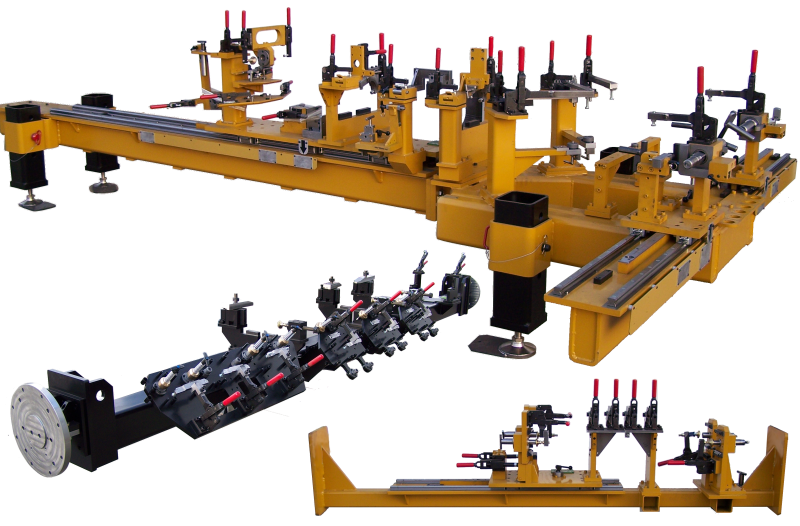

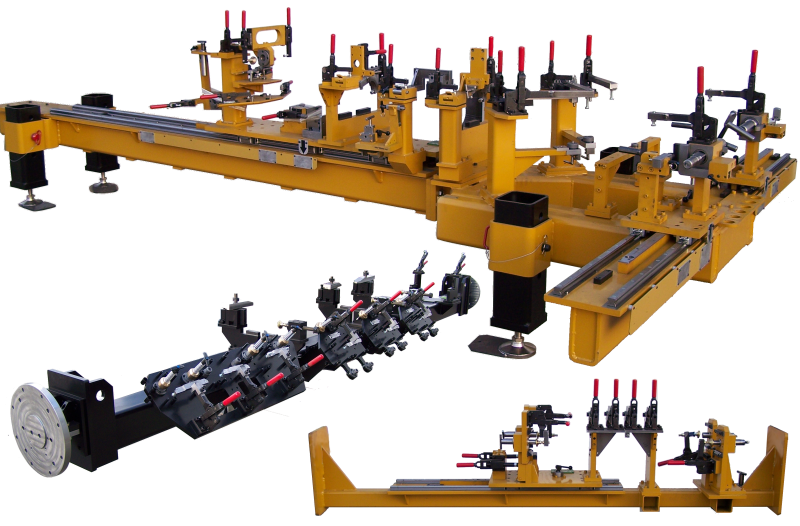

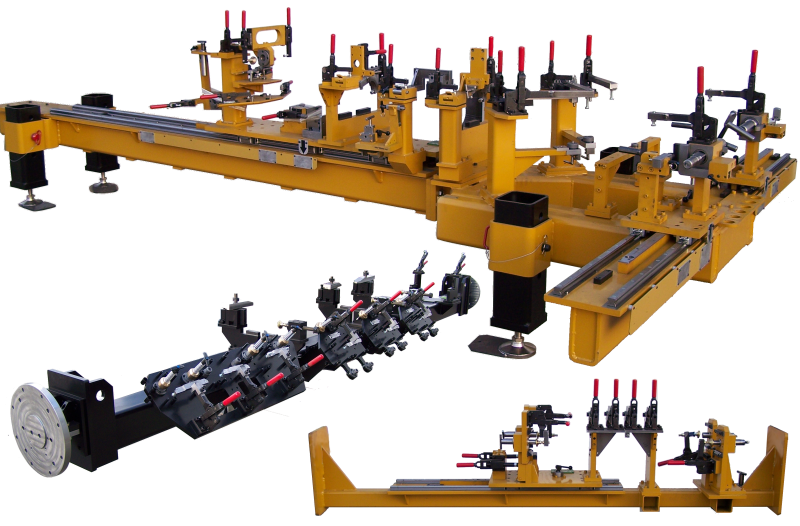

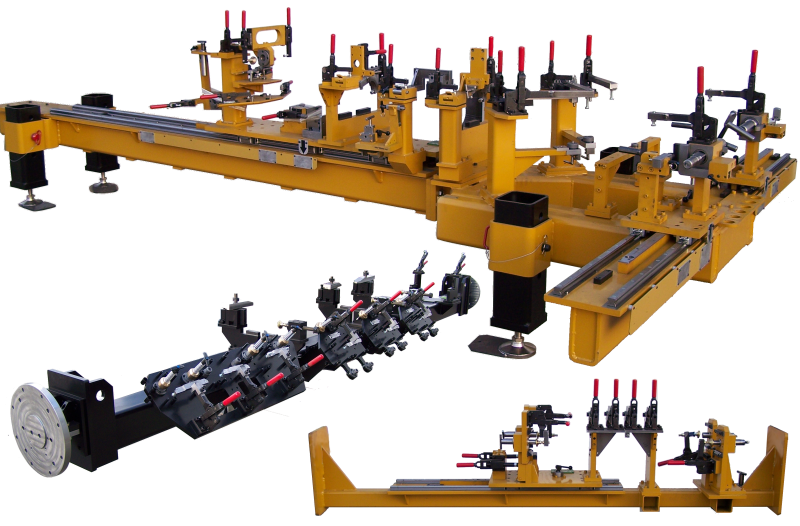

Northern Valley Machine has built numerous welding fixtures for various customers that range from fully automated to manually actuated, or combinations of each. In this particular instance, our customer supplied our engineering staff with an IGES solid model of their product, along with a detail print of welding callouts and GD&T. We used this information to generate a quote. After acceptance of the quote, we started with an initial design review with our customer to highlight goals of the fixture; welding access, safety controls, components to use, etc. Our Engineering staff then created a first revision of the fixture in SolidWorks, which was reviewed by our customer, and necessary changes were made to the model. Once the second revision was complete, a final design review was conducted. The model was then completed with detail prints, hardware requests, and assembly instructions. Once assembly of the fixture was complete, our customer came to our facility to verify the finished product with production parts. From acceptance of the quote to a finished product took place in just under 8 weeks. As an added bonus to our customers, they have the option of taking a complete fixture documentation package, which includes: SolidWorks based solid model and detail prints, DXF format prints of all machined components, BOM of all purchased components, and an IGES format solid model to be opened with any CAD system.

This fixture has approximately 120 unique machined components and 50 purchased components. Two-hand pneumatic safety controls were used to actuate the fixture. The controls were labeled and sequenced to ensure the operator loads components in the correct order, and unclamps in a specific order to reduce the chance of part damage. Pneumatic ejectors release the welded product from its hardened tool steel details.

Want to know more about weld fixtures or weld fixture options? Check out our Weld Fixture University